2008 Biesse Regal 520-1350 used widebelt sander

2008 Biesse Regal 520-1350 used widebelt sander

Location:Ontario, Canada

Description

2008 Biesse Regal 520-1350 used widebelt sander. Very clean, well cared for machine.

"note: click INSTANT PRICE anywhere you see it on our site to receive an instant auto-quote directly to your email!!"

Specifications

| Manufacturer | Biesse |

| Model | Regal 520-1350 used widebelt sander |

| Year | 2008 |

| Condition | Used |

| Stock Number | BBM2103 |

| Quality | Very Good |

| Electrics | 460V / 3 Ph / 60 Hz . transformer available for 600 volt. |

| * | All Descriptions, Specifications and Features are correct to the best of our knowledge. Interested buyers should verify before purchasing. |

Additional Features

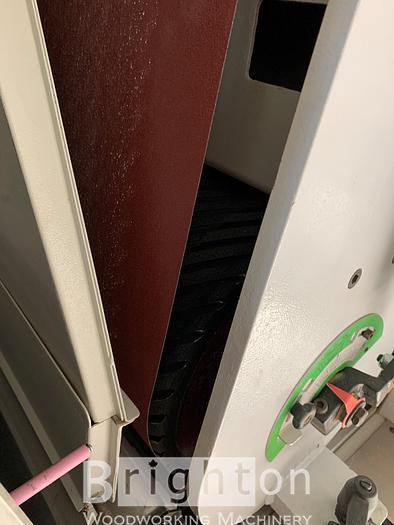

BIESSESAND REGAL 520 -1350 Wide Belt Sander,

2-Head.53" Width cap. and with Hard Rubber Drum, Combi head with Medium Durometer Rubber Drum and platen,.

Vacuum hold down feed belt powered by high pressure blower ,

Panel cleaning brush and rotary blow off air jets on out feed end of machine.

Head Configuration:

-- 1st Head: Grooved Calibrating/Sanding rubber roller. 300 mm dia. , 85 shore, 30 HP motor.

-- 2nd Head: Calibrating/Sanding roller and platen with 65 Shore rubber coating 25 HP motor . (Brand new, in box, Chevron belt available for $5000)

-- All heads with Sanding belt air jet cleaning.

Standard Equipment:

-- Base is monocoque shell type, nut and bolt free, constructed in thick steel tube, electro-welded using robot technology to guarantee maximum rigidity and precision.

-- Standard support rollers arrangement (1) on both infeed and outfeed. -

- Sanding Belt dimensions. 1,370 mm x 2,620 mm (54" x 103").

-- Min. and max. material thicknesses (1/8" - 8.5").

-- Feed belt speed 5/10 MPM (16.5 - 33 FPM), 60 Shore rubber belt.

-- Two-speed gear motor 1.1 kW (1.5 HP) feed drive; automatic conveyor belt tracking.

--Constant Pass Line (fixed table)

-- Dust extraction hood 160 mm (6.3") diameter.

Equipped with & Features:

-- Electronic Control unit running BIESSESAND "sanding machine software" Ver. 5.0. It displays Working thickness and feed speed, Delays and advances for timed operations.

-- Conveyor bed raises & lowers by (4) heavy duty trapezoidal screws anchored externally to the base, supported by thrust bearings and coupled by means of stiffener bars to guarantee perfect alignment and stability.

-- Electronic display of workpiece thickness.

-- Support rollers: one at the infeed and one at the outfeed end of the conveyor bed. -- Rubber coated pressure rollers located before and after each of the sanding heads. -- Electronic sanding belt tracking system.

-- Automatic StarDelta starter on main motors.

-- Automatic brake on sanding head motors.;

Accuracy of all specs needs to be verified by purchaser.