Cantek PR-1100 NDD used 3 head, Planer / Sander #BBM2506

Cantek PR-1100 NDD used 3 head, Planer / Sander #BBM2506

Location:Ontario, Canada

Description

Specifications

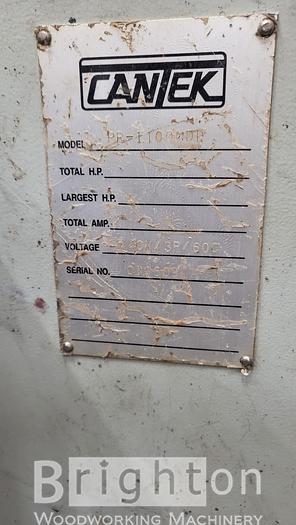

| Manufacturer | Cantek |

| Model | PR-1100 NDD used 3 head, Planer / Sander |

| Condition | Used |

| Stock Number | BBM2506 |

| Quality | Very Good |

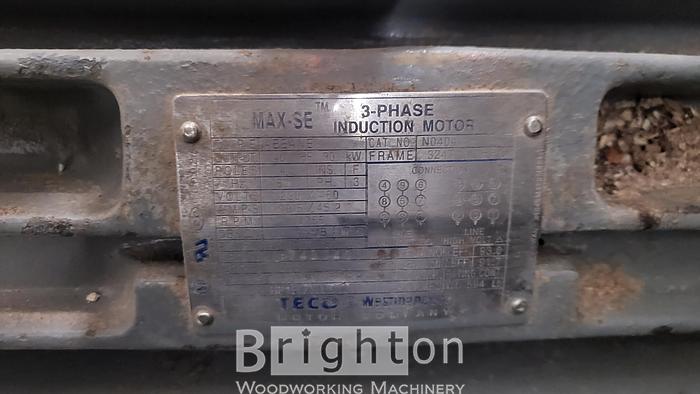

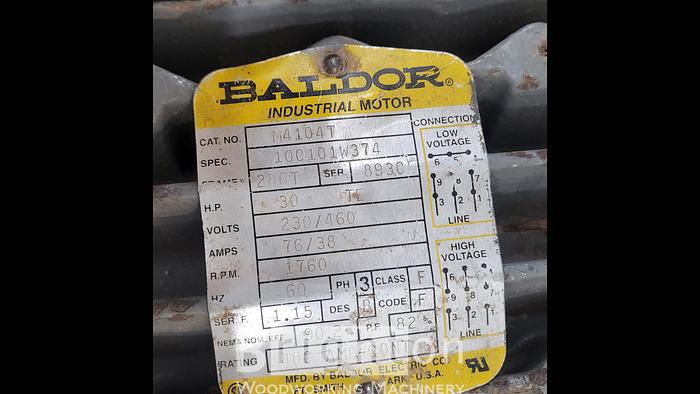

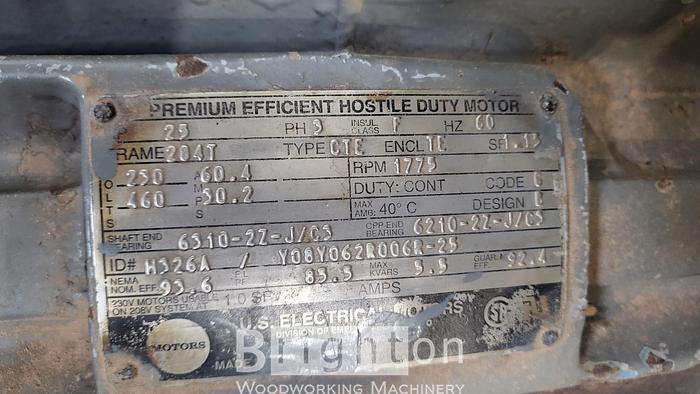

| Electrics | 440V / 3Ph / 60 Hz |

Additional Features

Extra sander paper included.

Head No. 1 Spiral Cutterhead

Solid steel Cutterhead 6” diameter, 6 rows inserts

Carbide knife inserts in spiral pattern for superior chip removal, minimum noise, and extremely smooth cutting effect

240 knives of 14x14mm x 2mm. Air wrench for knife change included

Cutterhead can be raised or lowered by turning a handwheel. A graduated scale is provided to indicate the thickness adjustment

Changing and rotating the knives is easily performed by opening the panel on the front of the machine and will open and close automatically by pneumatic cylinders. The cutterhead does not need to be removed from the machine.

Sectional infeed pressure shoe, spring loaded

Head No. 2 Contact Drum

10” dia. rubber grooved contact roller for added durability and superior stock removal

Head No. 3 Combination Head

6 ¼” dia. rubber contact drum followed by 3” platen for superior finish

The platen can be quickly removed for graphite and felt replacement

Sanding Belt Tracking

Pneumatic belt tracking with reliable send & receive type sensors

Microcomputer with Digital Readout

Table is raised and lowered by a digital controller

Conveyor Belt Tracking Control

The conveyor belt is pneumatically controlled to effectively prevent the fed belt from tracking off to one side

Conveyor Variable Speed Unit

The conveyor belt speed is controlled by inverter drive variable speed unit

Feed speed can be varied as desired to suit all types of planing/sanding requirements

Hour meter for maintenance control

Safety Features

Emergency stops on front and rear of machine

Safety push bar on infeed table

Safety lever bar will shut down the machine and prevent damage caused by feeding over thickness material

Full set of kickback fingers on cutterhead infeed for safety

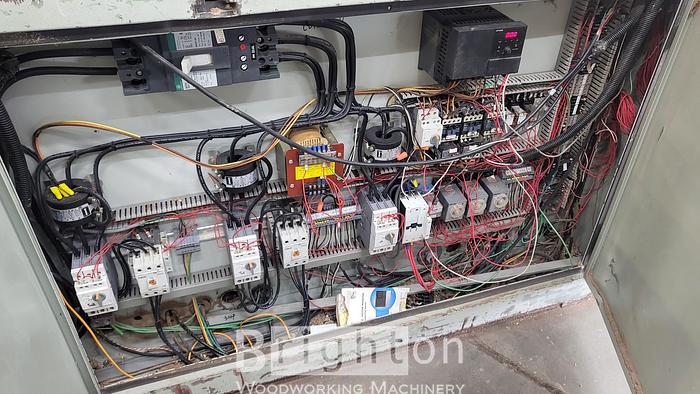

Centralized Control Panel

The central control panel is conveniently located to assist the operator to control the machine with ease – Electrics to CSA/UL Standards

Hold Down Pressure System

Infeed rubber pressure roller

Sectional infeed shoe, spring loaded, before cutterhead

Solid pressure shoe, spring loaded, before contact drum

Solid pressure shoe, spring loaded, before and after combination head

Outfeed rubber pressure roller

* All Descriptions, Specifications and Features are correct to the best of our knowledge. Interested buyers should verify before purchasing.