2007 SCM Tecnomax ME20 Used Edgebander #CBM2442

2007 SCM Tecnomax ME20 Used Edgebander #CBM2442

Location:Uxbridge, Canada

Description

2007 SCM Tecnomax ME20 Used Edgebander

Click INSTANT PRICE anywhere you see it on our site to receive an instant auto-quote, with Pricing and Specs, directly to your email!!

* All Descriptions, Specifications and Features are correct to the best of our knowledge. Interested buyers should verify before purchasing.

For leasing info call Lindsay at 905-758-0797 (mention Brighton Woodworking Machinery and BM# of machine)

For shipping quote, call Katharine at 905-663-2881 (mention Brighton Woodworking Machinery and BM# of machine)

Specifications

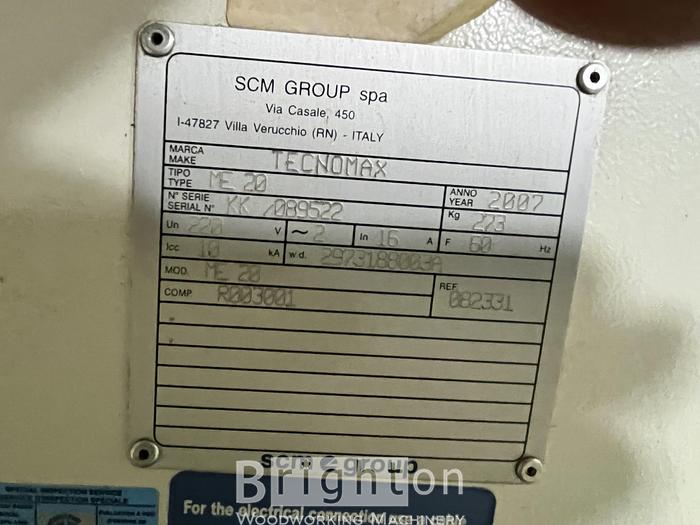

| Manufacturer | SCM |

| Model | Tecnomax ME20 Used Edgebander |

| Year | 2007 |

| Condition | Used |

| Serial Number | KK/089522 |

| Stock Number | CBM2442 |

| Quality | Very Good |

| Electrics | 220V / 1Ph / 60 Hz |

Additional Features

SCM Minimax ME 20 Automatic Edge Bander with Glue Pot

(info as taken from Manufactuer's website)

The SCM Minimax ME 20 is an entry-level, fully automatic edgebander. It has an automatic loader for edge rolls and a pneumatic guillotine unit which guarantees a clean, precision cut on the leading and trailing edges of the panel. It provides rapid setups when changing over from one edge band thickness to another.

ADVANTAGES:

Simple and intuitive: Error-free machining is ensured by the control panel positioned on the front of the machine, that allows an easy selection of all the main functions, among them, the operating units switching on and off. The PLC guides the operator during maintenance, cleaning, diagnostic operations, etc.

Ideal edge application: The glue is heated rapidly and evenly by the resistances. The automatic lowering of the glue temperature after a temporary halt in production when using the machine avoids burning of the glue. A new innovative system of self-lubrication of the glue pot, allows a more extensive use of the edge banding machine without the necessity of lubrication. Two rollers press the edge banding evenly and efficiently on to the panel edge. The glue spreading roller with electrical resistance inside provides a uniform glue spread and always at the maximum working temperature even on panels at the maximum working height.

Always precise when cutting: The efficient cutter ensures cutting always accurate. The reference is taken directly on the panel itself; consequently it doesn’t require any adjustment.

Quality finishing and versatility: The unit functions with slide copying pads to align perfectly to the work piece. These cutters are designed for straight or radius trimming of any type of edge, whether it is thick or thin, made of PVC, ABS, melamine, laminate or wood. The edge thickness is easily set by means of two numerical readouts.

Main Features:

Accessible and serviceable from the front of the machine via hood lift and strut. Control panel mounted on the front

Panel feed by means of a top feeder with high-adherence toothed belt with steel cables inside

Telescopic front support with rollers for the entire machine length

Hot melt glue with quick heat up system and internally Teflon coated to allow an easy glue replacement

Temperature adjustment of the applied glue integrated in the PLC control

Device for automatic recovery of unused glue

Automatic edge loading system for rolled edges with shear device for 2mm maximum thickness edges, and 50mm max height

End cutting unit: Guillotine end cut at 90°on the leading and trailing edges of the panel. Possibility to exclude the unit through the PLC control

Adjustable infeed fence with numeric readout of the edge thickness

Automatic lowering of the glue pot temperature after a temporary machine non-use

Superposed Trimming Unit. Equipped with vertical copying pads for an accurate positioning of tools with reference to the cutting point. The unit is provided with 72mm diameter, combined cutters: the radius part of the cutter is used to trim 2mm radius edges and chamfered thin edges

The straight part of the cutter is used for the trimming of edges in wood up to 5mm. Changing from radius edge to edge in wood is done easily moving the cutters axially. The edge thickness is shown by 2 numeric readouts.

95 PSI operating pressure

6 metres/min feed speed

Electrical requirements: 230v, single phase, 22 amps

Machine weight: 685 lbs

Required footprint: 52” x 93”

Required footprint: 52” x 93”

The machine can work 2 mm edges on panels up to 25 mm thickness, For thicker panels, results are granted with maximum thickness 1.5 mm

Made in Italy

Technical Features:

Working table dimensions: 1950 x 180 mm

Working table height: 904 mm

Min/Max rolled edges thickness: *0.4/2 mm (*0.6 mm minimum worktable PVC edge thickness)

Max. thickness of edges in strips: 5 mm

Min. / max. working height: 12 / 50 mm

Min. panel length / width with rolled edges: 180 / 65 mm

Min. panel length (frontal end cutting only): 120 mm

Feed motor power S1: 0.25 kW

Feed speed: 6m / min

Pneumatic operating pressure: 6.5 bar

Operating temperature: 190°C

Exhaust outlet diameter (base): 120 mm

Exhaust outlet diameter (glue pot): 60 mm