2023 BH Engineering BHZ12 Specialized (NEW) CNC machining center #NBM2386

2023 BH Engineering BHZ12 Specialized (NEW) CNC machining center #NBM2386

Location:Canada

Description

NEW Model BHZ12 Specialized CNC machining center.

- Designed for making MDF Doors.

- ATC Tool change machining center, 12 tools can be quickly switched

- Included tool holders

- High-power single vacuum pump to meet the needs of door making

- Efficient dust removal system

- User friendly software and free training

- Comes with designs for 10 door types and their required tools

- One Year Warranty

For pricing please click “REQUEST QUOTE” wherever you see it on our Brighton Woodworking Machinery website at www.brightonmachines.com.

Click <LEASE> for leasing information.

Click <SHIP> for shipping information.

* All Descriptions, Specifications and Features are correct to the best of our knowledge. Interested buyers should verify before purchasing.

Specifications

| Manufacturer | BH Engineering |

| Model | BHZ12 Specialized (NEW) CNC machining center |

| Year | 2023 |

| Condition | New |

| Stock Number | NBM2386 |

| Quality | Excellent |

| Electrics | 220V / 3Ph |

Additional Features

Weighted bed structure (welded structure, heat-treated bed)

• The heavy-duty structure design is adopted, and the material stress analysis and tempering vibration aging treatment are used to make the machine precision permanent without deformation.

• The base is completed by CNC gantry five-sided integrated processing to ensure all the corresponding geometric tolerance standards of the body.

Matrix vacuum adsorption table (anti-fold + PVC sheet)

• It is made of PVC sheet, which is wear-resistant, fire-resistant and never deformed.

• The multi-purpose matrix design can cooperate with the mobile vacuum suction cup to process the workpiece.

• The special arc groove design can prevent the rubber foam sponge from falling off and causing vacuum leakage.

Gantry (High Performance Design)

• Welded, stress relieved and precision machined steel plates up to 8mm thick.

• High vertical precision and stable operation.

Gantry slides (high strength, good verticality, long life)

• It is precisely machined from cast iron tooling plate, and adopts five-axis horizontal machining center to ensure verticality.

• Cast iron brackets provide vibration damping properties while providing rigid support for the gantry tubes.

• The unique dust-proof design of the linear slide can still travel unimpeded in the harshest environments.

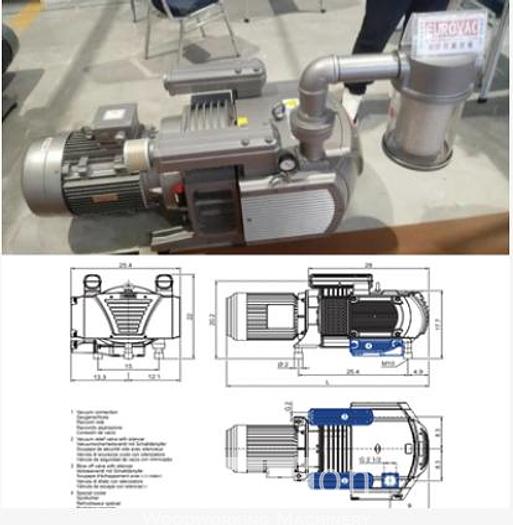

High-performance vacuum pump*2 (10 horsepower each)

• High-strength suction*2 to ensure the adsorption of various plates and small workpieces.

• Vacuum adsorption, long-term non-deformation, to ensure large adsorption force.

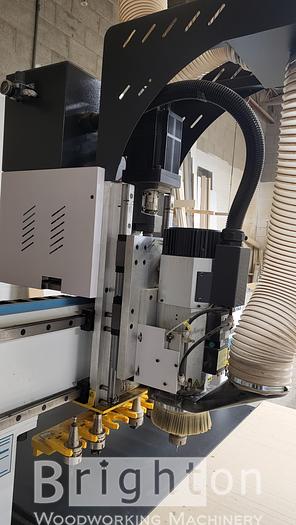

Air-cooled tool changer spindle (0-24000rpm)

• High rotational speed significantly improves production quality and increases tool life at the same time.

• Quick automatic tool change to ensure accurate clamping of tools.

• The unique dust-proof design of the linear slide can still travel unimpeded in the harshest environments.

Tool change machining center (straight row tool magazine)

• 12 tools in a row magazine.

• Optimize tool change time.

• Tool holders are built to last.

Automatic lube oil pump (adjustable refueling time and interval)

• Automatically inject lubricating oil into the required parts of the machine to ensure the smooth operation of the machine.

• Increase machine life.

• Save labor costs.

Tool setting instrument (automatic tool setting)

• Automatic tool setting, eliminating tedious steps such as tool change and parameter adjustment.

• Accurate and fast, greatly reducing errors.

Dust removal system (equipped with high horsepower dust removal motor)

• High horsepower dust removal motor to reduce the impact of dust.

• Double dust bag, double capacity.

Console (full-featured, movable)

• Quick functions such as emergency stop, start, pause, etc.

• The operating system is easy to learn and easy to operate.

• Handwheel simulation, safety testing.

Packaging (double insurance inside and outside the package)

• The whole body is fixed with wooden frame to avoid shaking and bumping.

• All-in-one package saves installation time.

Installation & Training:

• Machine operation training

o How to maintain the machine

o How to operate the machine safely

o How to work with software for fast and efficient production

o How to set a knife

o How to avoid emergencies

o How not to damage the machine

o How to perform simple repairs and maintenance on the machine

• Software use training

o How to use the software for quick order entry

o Basic custom drawing

o Simple modification of toolpaths

o How to use leftovers

o Typography settings

o How to export production files for machines

Maintenance and Warranty:

• BH Engineering will provide a 1-year warranty - including spare parts (factory default parameters) except consumables, all original mechanical parts, except for damage caused by improper use of the machine and external human collisions. In the scope of warranty, except for changes made to the machine by non-designated maintenance personnel and damage due to unnatural factors, it is within the scope of warranty

Included:

• Container unloading of the machine

• Installation and debugging of the machine

• Knife handle and tool holder set

• 10 door styles and required knives

Industry Applications:

1. Woodworking industry: three-dimensional wave board processing, processing of wooden doors, screens, craft fan windows, auxiliary processing of various furniture products

2. Advertising industry: advertising signs, logo production, acrylic cutting, blister molding, production of advertising products of various materials.

3. Mold industry: It can engrave metal molds such as copper, aluminum, iron, etc., as well as non-metal molds such as marble, plastic plates, and wooden boards.

4. Other industries: It can engrave various reliefs and is widely used in the craft gift industry.