2005 Homag Brandt KDN 650 C Used Edgebander #BBM2380

2005 Homag Brandt KDN 650 C Used Edgebander #BBM2380

Location:Ontario, Canada

Description

2005 Homag Brandt KDN 650 C Used Edgebander

Click INSTANT PRICE anywhere you see it on our site to receive an instant auto-quote, with Pricing and Specs, directly to your email!!

* All Descriptions, Specifications and Features are correct to the best of our knowledge. Interested buyers should verify before purchasing.

For leasing info call Lindsay at 905-758-0797 (mention Brighton Woodworking Machinery and BM# of machine)

For shipping quote, call Katharine at 905-663-2881 (mention Brighton Woodworking Machinery and BM# of machine)

Specifications

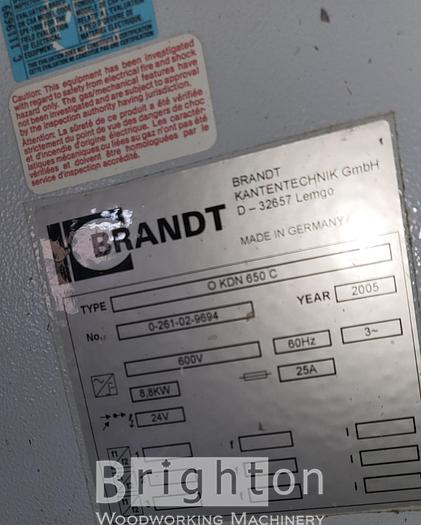

| Manufacturer | Homag |

| Model | Brandt KDN 650 C Used Edgebander |

| Year | 2005 |

| Condition | Used |

| Stock Number | BBM2380 |

| Quality | Very Good |

| Electrics | 600V /3 Ph / 60 Hz |

Additional Features

Brandt Edge Bander - Brandt KDN-650 Optimat Edge Bander

0.4 - 20 mm (0.016" - 25/32") Edge capacity, Panel thickness 8 - 60 mm (5/16" - 2-3/8"), Minimum panel length 160 mm (6-3/8") and 65 mm (2-1/2") minimum width

PC-16 Integrated Microprocessor Line Control for Programming the various Working Functions

Control Panel located at front of machine for operator convenience

Universal Automatic Magazine for Strip and Coil Feeding with strengthened precutter for cutting PVC from the coil, 800 mm Diameter coil table for large 3 mm PVC coils; includes solid wood in-feed device

Glue Station - Quick heat up Granulate Gluing System with large granulate hopper with automatic glue feed system, pre-melting unit between hopper and glue roller (required for glue demand of thick, long workpieces), glue temperature indication of both pre-melter and glue roller via LED thermostat display visible to operator; includes reversible rotation of glue application roller and retractable glue roller and infrared radiant glue heat zone control for optimum gluing strength

Pressure Section - First pressure roller driven and (4) idle pressure rollers, all with pneumatically controlled side pressure

End trim Station - (2) 1 HP motors, 12,000 RPM; straight and chamfer capability, Chamfer up to 15°. Program controlled pneumatic indexing straight to bevel

Top and bottom flush trimming station - (2) 2 HP motors, 12,000 RPM; with digital "Quickset" system. Includes straight insert cutters. Two position vertical indexing via program control

Top and bottom fine trimming station - (2) ¾ HP motors, 12,000 RPM; with digital "Quickset" system. Tilt range 0 - 25°. Includes 3 mm insert cutters. Program controlled pneumatic indexing

Scraping Station with Knives - For scraping of roughly trimmed PVC edges in order to remove cutter marks; includes digital "Quickset" system for lateral positioning of top and bottom scraping knives and program controlled pneumatic indexing; equipped with auto control blowoff nozzle.

Flat glue scrapping.

Top & bottom buffing Station - (2) 1/3 HP motors, 2,800 RPM, inclinable vertically and horizontally

Feed chain track speed - 46 FPM; 3 HP feed drive

Equipped with digital height indicator, Electronic Frequency Changer for all trimming motors.

Controller screen does not work. It comes with external monitor which is much larger and easier to see than the original control screen.