2013 SCM Cyflex F900, used CNC universal routing, boring and grooving centre #BM2212

2013 SCM Cyflex F900, used CNC universal routing, boring and grooving centre #BM2212

Location:Ontario, Canada

Description

Like NEW! SCM Cyflex F900, used CNC universal routing, boring and grooving centre. Cost when new $73,000 CAD

Click INSTANT PRICE anywhere you see it on our site to receive an instant auto-quote, with Pricing and Specs, directly to your email!!

* All Descriptions, Specifications and Features are correct to the best of our knowledge. Interested buyers should verify before purchasing.

Specifications

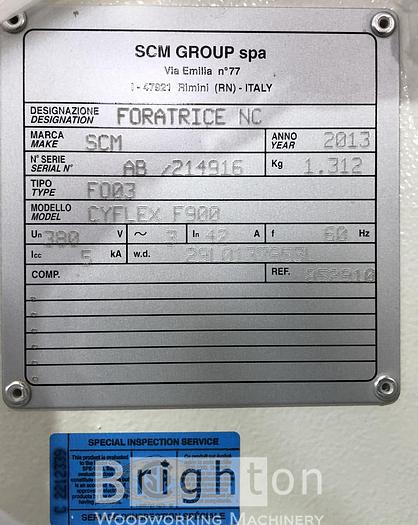

| Manufacturer | SCM |

| Model | Cyflex F900, used CNC universal routing, boring and grooving centre. |

| Year | 2013 |

| Condition | Used |

| Stock Number | BM2212 |

| Quality | Very Good |

| Electrics | 600V / 3 Ph / 60 Hz with included transformer. Machine is 400 |

Additional Features

SCM CYFLEX F900, CNC routing, boring and grooving centre with a fixed work table.

The Cyflex F900 is a CNC-machining centre with almost upright machine table.

The workpiece is clamped and moved via the collet chuck. This way the motion of the x-axis can be achieved, which leads to an utterly space-saving machine concept.

MAIN ADVANTAGES

EASY-OF-USE AND FLEXIBILITY no operator's intervention for worktable toooling.

COMPACT very compact overall dimensions.

HIGH PERFORMANCES and very high power with Xilog. Possibility to

integrate the machine in a working cell thanks to Netline technology.

TECHNICAL DATA:

AXES

Max. panel length, 3.050 mm

Min. panel length, 150 mm.

Max. panel width, 900 mm.

Min. panel width, 70 mm.

Max. panel thickness, 50mm.

Min. panel thickness, 10 mm.

Max. X axis speed, 40 m/min.

Max. Y axis speed, 40 m/min.

BORING HEAD

Vertical spindles, 7 in X, 5 in Y

Horizonal Spindles, 4 in X, 2 in Y

GENERAL FEATURES

CNC routing, boring and grooving centre with a fixed work table.

It is capable to carry out all horizontal and vertical boring, routing and grooving on various types of materials (chip-board, mdf, plastics and light alloy).

Base and working table

structure made of welded steel plates to create a large tilted support surface, on which the work tables are fixed. Electrical cabinet integrated in the base.

Work table made of phenolic material with grooves to allow the through boring

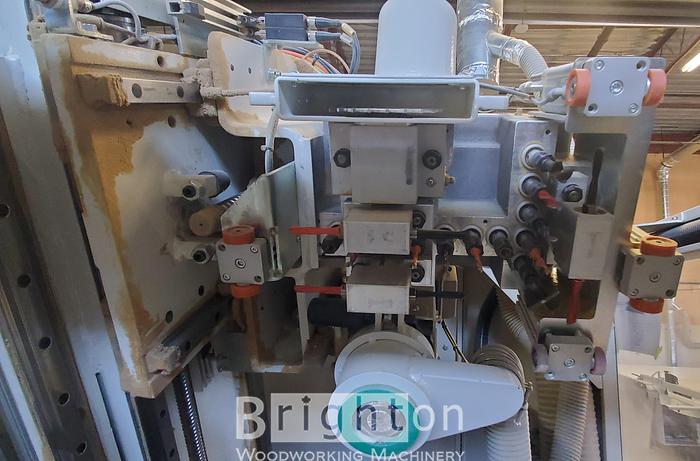

Mobile upright:

The gantry structure is made of welded steel plates which supports the main operating group.

Operating group

consisting in boring head with 12 vertical/ 6 horizontal spindles and integrated blade

Movement of workpiece and operating group

An intelligent clamp directly controlled from the NC locks the panel to be processed and positions it in sequence under the operating head to execute the requested machining

Sliding along "X", "Y" and "Z" axes of prismatic linear guides and preloaded recirculating ball bearings.

Axis transmission through recirculating ball screws with preloaded system.

Group positioning and machine motion is carried out by means of digital brushless motors.

CNC CONTROL UNIT

Control Unit designed for Boring and Routing Centres and Xylog operator interface installed on PC

Pc-Office

- Windows XP operating system

- 17" LCD colour display

- Qwerty keyboard

- Xylog Plus2 interface machine software

General features of the Xylog Plus2 software

Programming

- parametric, graphic and ISO programming;

- import of the DXF and ASCII files (2D);

- guided editor with graphic and syntactic help screens;

- automatic optimisation of boring cycles

- panel origin change to carry out processing of workpieces with special shapes or profiles;

Included accessories

- on-line calculator of computed data;

- simulated program execution;

- use of bar codes with already integrated software;

- selfdiagnosis and signalling of possible errors or damages in the user's language;

- single step operation for manual control of individual program steps; Configuration

- operator interface in user's language (I - GB - F - D - E);

- machining head graphic configuration;

- double override which allows to adjust the operating unit positioning speed;