2007 LOBO DA3775L Used Wide Belt Sander

2007 LOBO DA3775L Used Wide Belt Sander

Location:Uxbridge, Canada

Description

Nice, very heavy duty, Dual head, 36 inch, used Lobo wide belt sander.

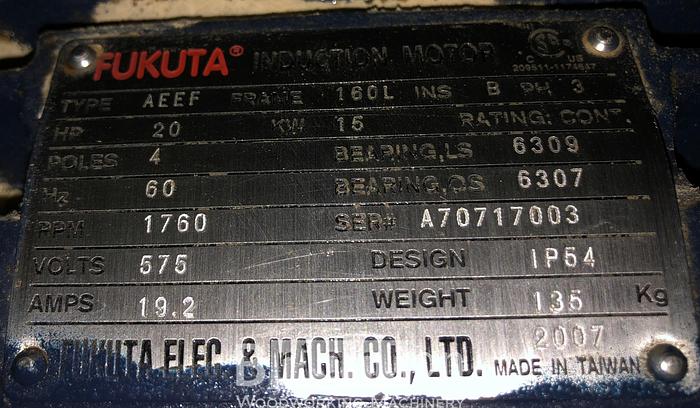

Total 37.5HP motors: 1-20HP, 1-15HP, 1-2.5HP. 2007 LOBO DA3775L Used Wide Belt Sander.

Click INSTANT PRICE anywhere you see it on our site to receive an instant auto-quote, with Pricing and Specs, directly to your email!!

* All Descriptions, Specifications and Features are correct to the best of our knowledge. Interested buyers should verify before purchasing.

Specifications

| Manufacturer | LOBO |

| Model | DA3775L Used Wide Belt Sander |

| Year | 2007 |

| Condition | Used |

| Stock Number | BM2200 |

| Quality | Very Good |

| Electrics | 575V / 3 Ph / 60 Hz |

Additional Features

2 head 36 inch wide belt sander.

1st head drum with 20hp motor.

2nd head combi with 15hp motor.

With the LOBO Two Head Wide Belt Sander, you can accurately, heavily sand your stock with the first drum head and with the second combinational head you can give the unlimited fine finish.

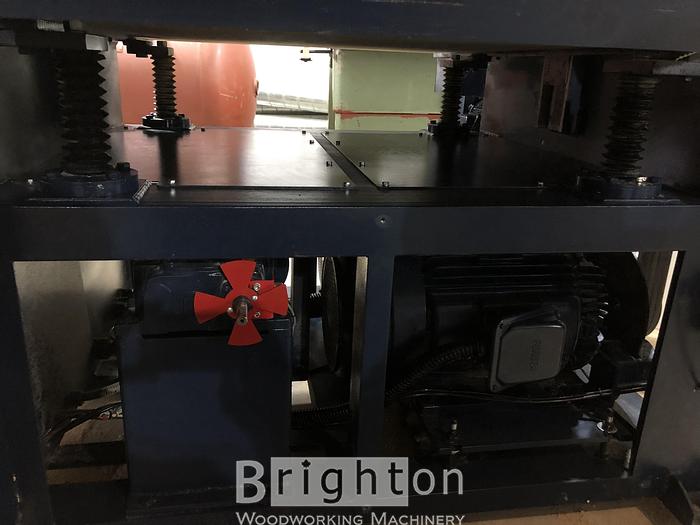

Rugged heavy-duty sheet metal construction designed for durability usage.

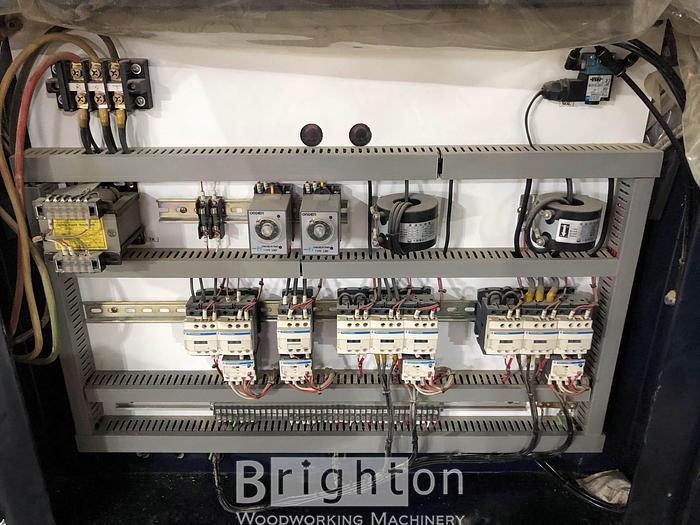

Full power industrial motors drive sanding and auto infeed smoothly.

Infeed and outfeed are spring-loaded hold down rollers to ensure positive feeding without sanding mark.

Combination platen & drum sanding head for best sanding choice such as:

1. With the platen up, the sander functions as a drum only machine, for sanding with a 40 ~ 100 grit belt.

2. With the platen and drum same level, intermediate and final finishing is possible, using a grit of 120 ~ 180.

3. With the platen down (below drum), used for the fine finishing or lacquer sealer sanding, with 180 ~ 600 grit.

Sanding platen with a quick release and lock down designed for easy removal or loading of graphite platen.

Computerized thickness adjustments control with accurate digital readout, just key in the size you desire and automatic table movement for sanding thickness within 0.005" accuracy.

Large size diameter contact drum is dynamically balanced rubber covered spiral grooves, designed to provide considerable advantages for the effective removal of material.

Special rubber feed belt for safe non-slipping, transporting the workpieces.

The abrasive belts are tracked by oscillating cylinders linked to the upper roller. The edge of the belt is detected by electric eye sensor which in turn control the air supply to the position via solenoid value. One limit switch is located on each end on top roller of the sand paper for quick stop in case of the event of belt breakage.

Main table designed with the convenient leveling adjustment which ensures greater stability with excellent tolerance they provide variable from 0" ~ 5" range sanding thickness.

4 heavy-duty jackscrews powered conveyor table elevation.